Article: Candle Testing - The Definitive Guide

Candle Testing - The Definitive Guide

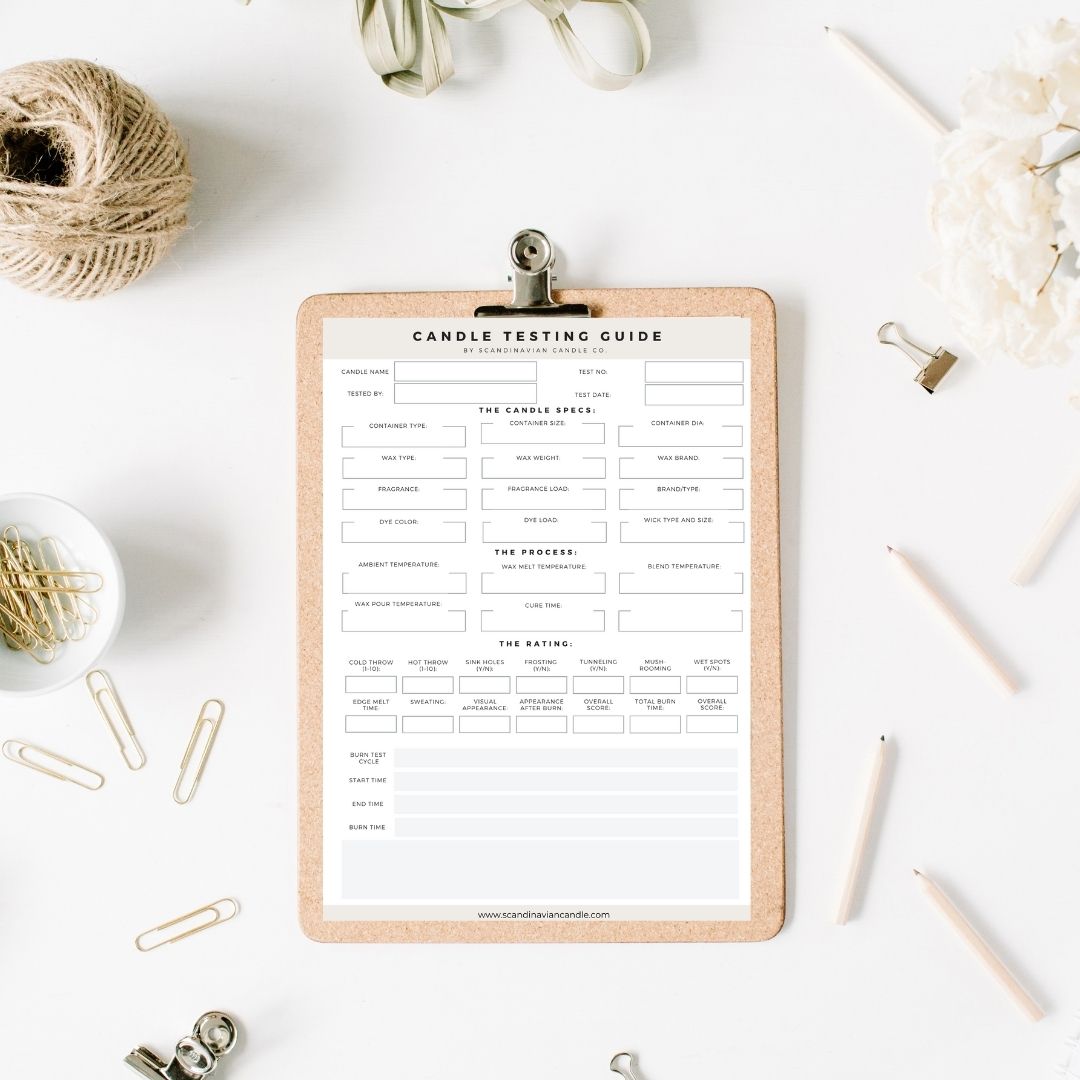

I hate to admit it, but in the beginning our testing process was a mess. While we were testing a lot, I had a hard time remembering what the testing parameters were for each candle. This is why we created this Candle Testing Guide. It will allow us to record all the different testing parameters on a single sheet of paper so that we can easily recreate success or avoid the same errors over again.

Sign up HERE to get it sent to your inbox for FREE

But first, let's dive into why testing the candle is important. So you have made your first container candles, perhaps with our luxury candle making kit, and now you are ready to start experimenting with different containers, wax, wicks, and fragrance oils. Maybe you already have an idea of how your perfect candle should be composed, or you want to try out different combinations to create your signature scented candle.

As a beginning candle maker, you will soon learn that testing, testing, and more testing will never go out of fashion.

When doing many experiments, it will help a great deal being organized and have an easy, coherent system that allows you to go back and check the parameters used when you finally did a successful test, or it became a disaster.

By using our test template, we record the type of supplies we are using and the most important process parameters for the testing to easily recreate the success or avoid the same mistake during the next testing.

We prefer to divide the testing template into three main sections: "The Candle Specs.", "The Process" and "The Rating". Let's go through each of these sections below and start with how we rate a candle.

The Rating - What Makes a Great Candle?

What is the benchmark for the perfect scented candle? This is hard to answer since it is quite subjective, but if you are like us, we think these main factors are important for a candle customer:

- How is the cold and hot throw of the candle?

- How is the visual appearance of the finished candle?

- How is the visual appearance after consecutive burn cycles of the candle?

- What is the burn time of the candle?

How to score the scent throw is subjective. Some people love a powerful and potent scent that fills the whole room, while others prefer a more delicate and noticeable scent that is present but without being too dominant.

When testing several candle combinations, the best thing is to set your own benchmark and score based on your preferences or based on your what your customer avatar will love. In our testing template, we choose to score the cold and hot throw on a scale from 0 to 10, with 10 being the most potent throw.

To score the finished candle's visual appearance, we check if the top is smooth and even if it has signs of sinkholes or frosting? We use a yes/no score for this, but a number scale can also easily be used if needed.

During and after the first test burn cycle (usually between 2 and 4 hours), we also look at signs for mushrooming of the wick, or if we are getting a tunneling effect, or the time it takes for the wax melt pool to reach the edges of the candle vessel. We also look for sweating - small pools of fragrance oil that may show up on the candle's surface.

It is possible to calculate the burn time theoretically, but we also like to conduct a proper and full burn test of a candle to check the practical burn time. We do this by burning the candle in cycles of 2-4 hours until all the wax has evaporated. In the testing guide, we note the start and end times between each burn cycle and calculate the total time.

The Specs - What Type of Supplies Did You Use?

It is important to record all the supplies you used to make the candle, which may help us understand what materials to keep and what to change during further testing. In our testing template, we record information about:

- What type of candle wax we are using - how much - and from what brand or supplier.

- What kind of vessels are we using - what volume size - and the diameter from edge to edge.

- What candle wicks we are using - type and size.

- Fragrance Oils - what type - what brand and the percentage of fragrance or weight (fragrance load).

- Fragrance Dye - what color and how much.

As you may know, already - one type of wax quality may work perfectly in combination with a certain type of fragrance oil and a wick size, but when changing the wax or scent, you may get a different result with the same wick.

We have found that pure soy candles require a thicker cotton wick thread size than candles made of paraffin wax. We also often see that the type of fragrance may impact the candle's visual appearance even if the wax is the same. If we change from one candle jar diameter to another, finding the proper wick type and size requires testing. Make sure to write down all the different combinations to tweak the testing as required easily.

The Process - How did you make it?

In this section, we record the important process variables during the process. Weather you use a double boiler method or a presto pot or similar, It will be important to have a candle thermometer handy for this part:

- Ambient temperature - What is the temperature in your workplace?

- Wax melting temperature - To what temperature do you heat the wax?

- Blend temperature - At what wax temperature do you mix the melted wax with the fragrance oil.

- Pour temperature - At what temperature do you pour the wax into the candle container.

- Cure time - how long do you let the candle cure before you start testing and rating it.

These process parameters are very important and you may see different results by tweaking these. Especially the blend temperature is important as you have to take the flash point of the fragrance oil into account, but also the pour temperature could impact the visual appearance of the finished candle.

To sum it up - mastering candle making requires that we have control the supplies we use and the process. It is a bit technical, but it is really not that difficult. The key, in our opinion, is to test, learn and experiment.

Now, ready to get your free candle testing guide?

If this testing process sounds good to you, just sign up HERE to get our proven candle testing cheat sheet sent to your inbox for free. We have found it very useful and hope it can bring some value to you as well.